AI-generated podcast conversation: Spotify, Apple, RSS

AI-generated summary: The text examines the lifecycle of oil wells, detailing the various waste streams generated during drilling, hydraulic fracturing, production, and post-production phases, with produced water being the most significant. It then shifts focus to SECURE Waste Infrastructure (SECURE), a major player in managing these waste products across Western Canada, outlining their vertically integrated operations including waste processing facilities, landfills, and saltwater disposal wells, in addition to metals recycling and energy infrastructure services. Finally, the text traces the historical consolidation within the Canadian hydrocarbon waste management industry, highlighting SECURE’s emergence as a dominant force through strategic acquisitions, particularly its merger with Tervita, and discusses the company’s current competitive landscape, operational stability, and financial strategies.

(all $ CAD)

I.

There are several phases in the lifecycle of an oil well and different kinds of waste generated in each of those phases.

When drilling a well, specially engineered fluids are pumped through the drilled hole (wellbore) to cool the drill bit, lift rock and soil fragments up to the surface, and maintain a level of pressure that prevents oil and water from surging uncontrollably. After the hole is drilled, it has to be prepared to draw out the oil. In tight shale formations, this often involves hydraulic fracturing, where water, sand, and chemicals are pumped deep into the well at high pressure, creating small fractures in the rock that allow oil or gas to flow into the well. Some of the injected fluid, known as flowback water, returns to the surface as a waste product.

At this point, the well enters its production phase, delivering a continuous stream of oil, water, gas, and sometimes sand. This slurry flows into a pressurized vessel at the production site, where the oil and water are separated and stored in different tanks. Any material that can’t be separated in this first filtering step is routed to an emulsion tank, where the heavier sludge settling at the bottom is dealt with later at a dedicated facility. During production, the most voluminous waste stream, comprising ~80% of well waste, is produced water: the salty, contaminated water that emerges alongside the oil and gas it has been trapped alongside within the same rock layers for millions of years.

That wastewater accounts for such a disproportionate mix of the waste stream is a natural consequence of physics and geology. Water is denser than oil, so in a typical reservoir it tends to settle below the oil. But it is also less viscous, meaning it flows more easily. So, as oil is extracted, pressure near the wellbore drops relative to the surrounding reservoir, drawing water upward from below (fluids naturally move from areas of higher pressure to lower pressure). This phenomenon, known as water encroachment, becomes more pronounced as a well ages and the pressure difference increases. And as the reservoir’s natural pressure declines, operators often inject water – sometimes even the very produced water recovered earlier – into mature wells to sweep remaining oil from the rock pores and toward the wellbore, which in turn generates even more wastewater.

Once all economically recoverable hydrocarbons have been produced, the well and its surrounding area must be cleaned up to meet regulatory standards. Drilling mud and specialized fluids are pumped in to flush out debris and block the flow of oil and water into the well. Cement is then injected to seal off specific sections, creating a hardened, impermeable barrier that prevents fluids from rising to the surface or moving between underground layers, where it could contaminate freshwater aquifers. The surrounding soil, contaminated throughout the life of the well from small leaks, must be hauled away; tanks, wellheads, concrete pads, piping and other surface equipment must be demolished and cleared.

II.

Every natural ecosystem has its own waste managers - scavengers that consume carrion, bacteria that break down manure, and detritivores that vacuum organic debris from the ocean floor. The oil and gas industry has its own equivalent: an inconspicuous set of companies that deal with the waste left behind by hydrocarbon extraction, salvaging what can be reused and safely disposing of what cannot. The largest of these bottom feeders is SECURE Waste Infrastructure (SES.TO), which operates more than 80 facilities across Western Canada (~95% of revenue) and North Dakota1 (~5%).

The Western Canada Sedimentary Basin (WCSB) is the engine of Canada’s oil and gas industry, holding the bulk of its conventional fields – older, porous, and permeable rock like sandstone and limestone – along with oil sands, where a thick, tar-like crude called bitumen is trapped in shallow sand and clay, and unconventional plays, such as tight sandstone, shale, and siltstone, where hydrocarbons won’t flow without stimulation. Alberta is the beating heart of the WCSB – containing the basin’s thickest sedimentary layers and most of its production activity – and home to most of SECURE’s assets.

SECURE’s waste management infrastructure is made up of three, vertically integrated parts: Waste Processing facilities (aka, “Process, Recovery, and Disposal” facilities, or PRDs), Salt Water Disposal wells (SWDs), and landfills.

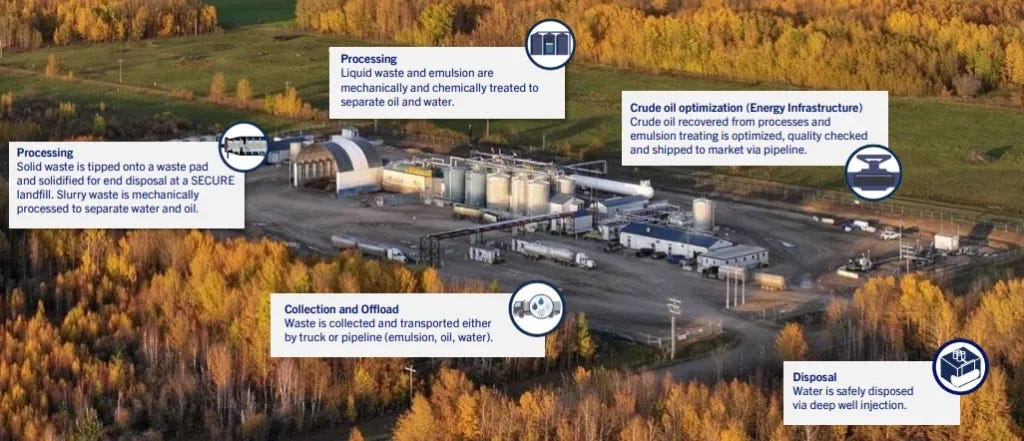

Waste processing facilities, like the one featured below, are the backbone. The 55 that SECURE operates (40 in Alberta, 6 in Saskatchewan, 5 in British Columbia, and 4 in North Dakota) receive emulsion and slurry waste from the wellsite, typically by truck, and use a combination of heat, chemicals, and centrifuges to break it apart into oil, water, and solids. Oil recovered from emulsions is returned back to the customer, while oil extracted from slurry is sold into the marketplace, with around half the resulting revenue shared with producers. Wastewater, either extracted from the emulsion/slurry or shipped directly from well sites, is injected at a disposal well on premises or pipelined to one a few kilometers away. Any remaining solids are transported to one of SECURE’s 12 owned or 2 contracted landfills (8 in Alberta, 4 in Saskatchewan, 1 in each of BC and Manitoba).

PRDs are generally SECURE’s most capital intensive projects, requiring anywhere between, say, $20mn and $50m of investment to build, with the amount varying depending on location. With somewhere around 90% of treatment volumes tied to production, revenue is very predictable from one year to the next, with ~half of it dropping down to EBITDA.

Source: SECURE Waste Management; May 2025 Investor Presentation

Downstream of its waste processing facilities, SECURE operates two types of landfills. Most are Class II sites, permitted to accept non‑hazardous solid waste such as drill cuttings, spent drilling mud, demolition debris, and soil contaminated below regulatory thresholds. One site, however, carries a rarer Class I designation – one of only two such landfills in Western Canada, the other run by Clean Harbors – allowing it to handle more toxic materials like highly contaminated soil and chemical plant residues. In addition to landfills, SECURE operates an underground cavern lined with impermeable salt, designed to permanently contain high‑fluid, slurry‑type waste that poses a greater risk of leaching if placed in a conventional landfill.