[SNA – Snap-On] when brand meets distribution

Snap-On’s origin coincides with that of the US auto industry. In 1920, an engineer by the name of Joseph Johnson created a set of 10 sockets of varying dimensions that interchangeably “snapped on” to 5 different handles, allowing mechanics to rationalize their toolset (“5 handles could do the work of 50”). When presenting to garage mechanics, Snap-On salesmen were advised to dramatically lay out the socket on clean green felt, in much the same way a surgeon might lay out their surgical instruments, imbuing the steel wrenches with a halo of quality that reflected the lofty standards by which they were manufactured.

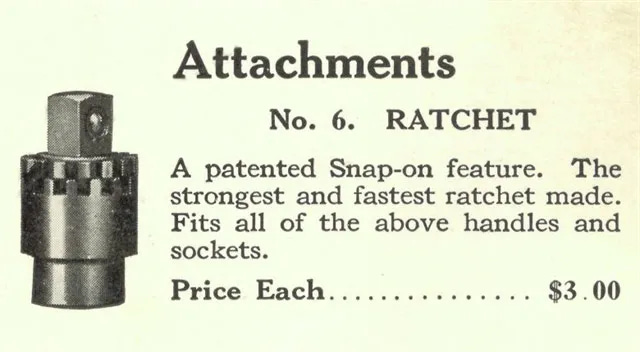

Snap On’s first patented ratcheting attachment, filed in 1923 (source)

The booming ‘20s witnessed a explosion in not just in auto production but variety as well, and as the number of car models expanded, so too did the number of customized tool kits that Snap-On offered. When the decade collapsed into the Great Depression, Snap-On provided financing for its products to struggling mechanics, birthing a primordial version of the Snap-On Credit program that was formally launched in the 1960s and remains a fixture to this day. Tool innovation continued apace. In the late ‘30s, Snap-On rolled out a patented line of “torqometers” that could measure and apply precise torque a fastener. Soon after, the company was pressed into service during WW2, during which time it began manufacturing its products from nickel alloy steel to meet the military’s demanding materials specification. To better address shortages in the civilian market, Snap-On salesmen would stock their personal vehicles with tools that they purchased directly from Snap-On, drive to local auto shops, and re-sell them to mechanics. In putting their own capital to work, Snap-On salesmen became “independent contract distributors”. This mobile selling approach would be formalized into a franchise model in 1990.

Snap-On expanded beyond hand tools and began selling big ticket items to garages rather than to the mechanics working in them. The introduction of wheel aligners was, through the acquisition of Weidenhoff Corp in 1956, followed by the launch of voltmeters that diagnose electrical issues, ammeters that measure the flow of electricity, alternator testers that track voltage from the alternator to the car battery, and anal-o-scopes (very unfortunate naming there) that identify engine and electrical malfunctions. Alongside those diagnostic devices, Snap-On expanded plant capacity to manufacture tool storage cabinets, which it had previously sourced from third parties. Moreover, whatever presence Snap-On had outside the automotive market expanded during and after the 1940s, with the launch of custom hand tools for railroad maintenance, aircraft, and heavy military equipment1.

With Snap-On broadening its purview by product, industry, and even geography, through organic growth and acquisition, revenue exploded over the next few decades, from $28mn in 1960 to $77mn in 1970 and $378mn in 1979, a year after the company’s shares were listed on the New York Stock Exchange. By 1992, sales crawled toward $1bn.